In the world of manufacturing and distribution, efficient and secure product packaging plays a pivotal role in ensuring products reach consumers safely while maintaining their appeal. One of the most revolutionary innovations in the packaging industry is the shrink tunnel machine. This piece of equipment has transformed the way products are packaged, offering benefits like improved efficiency, cost-effectiveness, and a professional finish. If you’re involved in product packaging, understanding how shrink tunnel machines work and why they are a game changer could be a game changer for your business.

What is a Shrink Tunnel Machine?

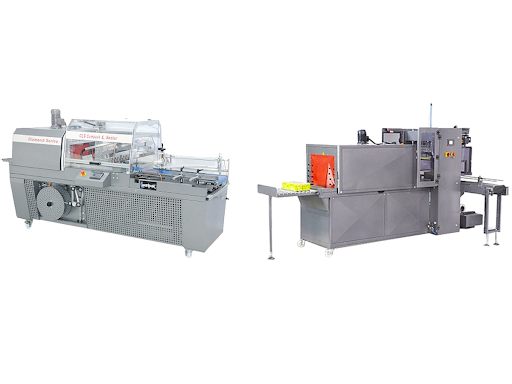

A shrink tunnel machine is a device used in packaging lines to apply shrink film around a product or a group of products. The shrink film is usually made from materials like polyolefin or PVC. Once the film is wrapped around the product, the shrink tunnel uses heat to shrink the film tightly, securing it around the product. The result is a tight, professional-looking package that protects the product from damage during storage and transportation.

Shrink tunnel machines come in various sizes and configurations to accommodate different types of products. From small items like bottles and cosmetics to large items like boxes and electronic goods, shrink tunnels are versatile enough to handle a wide range of packaging needs.

Benefits of Using Shrink Tunnel Machines

Increased Efficiency

One of the biggest advantages of using a shrink tunnel machine is the increase in packaging efficiency. Manual packaging methods can be time-consuming and prone to errors. By automating the shrink-wrapping process, businesses can significantly speed up production times. Shrink tunnel machines are designed to be fast, able to wrap hundreds or even thousands of products in a relatively short amount of time. This increased efficiency helps businesses meet high demand and reduce labor costs associated with manual packaging.

Professional and Consistent Results

Shrink tunnel machines deliver a high level of consistency and professionalism. Unlike manual packaging, which may result in uneven shrink wraps or unsightly packaging, a shrink tunnel ensures that each product is consistently wrapped with a tight, secure finish. This professional appearance not only improves the visual appeal of the product but also enhances its shelf-life and durability, offering an added layer of protection from dust, dirt, and moisture.

Cost-Effectiveness

While the initial investment in a shrink tunnel machine may seem significant, the long-term savings are undeniable. By increasing efficiency and reducing labor costs, businesses can recoup the cost of the machine in a relatively short amount of time. Additionally, shrink wrap is often more affordable than other forms of packaging like boxes or rigid containers, making it a cost-effective alternative for many businesses.

Versatility

Shrink tunnel machines are incredibly versatile and can be used for a wide variety of products. Whether you’re wrapping individual items or grouping multiple products together, shrink tunnels can handle it. The machines can be used in industries ranging from food and beverage to electronics, pharmaceuticals, and more. The ability to package different types of products using the same machine adds significant value to businesses, as it eliminates the need for multiple specialized machines.

Improved Product Protection

Shrink wrapping provides an excellent way to protect products during transportation and storage. The shrink film forms a tight, durable seal that keeps the product safe from external elements such as dust, dirt, moisture, and tampering. In industries where product integrity is critical, shrink tunnels help ensure that products remain in pristine condition until they reach the consumer.

How Shrink Tunnel Machines Work

The process of using a shrink tunnel machine is straightforward yet highly effective. The first step involves placing the product into a pre-formed shrink film sleeve. This film is typically fed through a conveyor belt system, which moves the products into the heat tunnel. The heat generated inside the tunnel causes the shrink film to contract, tightly wrapping around the product.

As the product moves through the tunnel, the temperature is carefully controlled to ensure optimal shrinkage without damaging the product or the film. Once the product exits the tunnel, it is securely wrapped and ready for further handling, including labeling, shipping, or distribution.

Conclusion

Shrink tunnel machines have undoubtedly revolutionized the packaging industry. With their ability to increase efficiency, provide consistent results, and reduce costs, they have become an essential tool for businesses of all sizes. Incorporating advanced technology like the PE Bundler and specialized shrink tunnel machines into your production line can significantly enhance the effectiveness of your packaging process, enabling your business to meet the evolving demands of consumers while improving both product safety and aesthetic appeal.