We control the pressure and flow of compressed air using high-pressure valves. Which inflate preforms before shaping them into final products. The manufacturing process becomes cost-efficient and safe during the blowing stages. Where the operators control the valves to achieve the product’s stiffness.

This post aims to provide an overview of the importance of high pressure valves in PET blow molding machines, along with their functions, types as well as their contribution to the maximum operational efficiency of the machines.

The Role of High-Pressure Valves in PET Blow Molding Machines

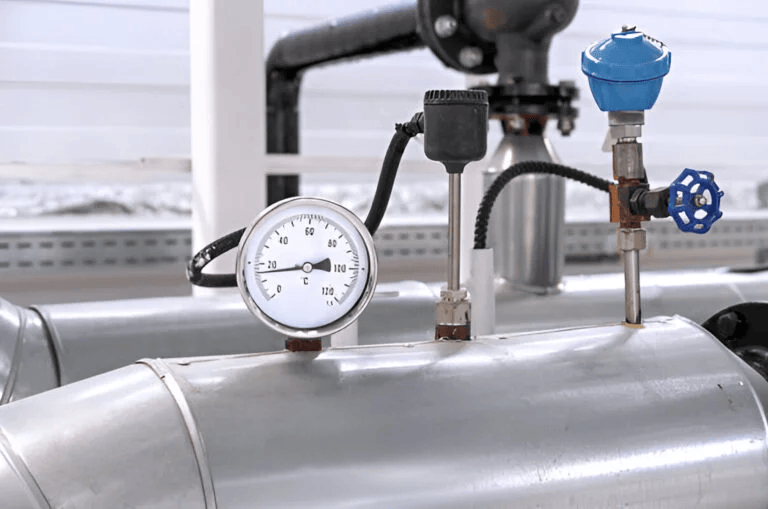

High pressure valves are a crucial part of the PET blow molding machine that controls the air flow and pressure within the machine. Their precise regulation is particularly important for product quality control.

Types of High-Pressure Valves Used in PET Blow Molding

1. Solenoid Valves: In PET blow molding machines, electronic command valves switch the compressed air supply with speed and precision. They are usually used to define blowing cycles.

2. Check Valves: These do not allow airflow from outside to the inside which helps to direct the airflow inside the system.

3. Pressure Relief Valves: These valves will automatically get rid of extra pressure so as to prevent destruction of any equipment. Such valves are important in ensuring that the PET blow molding machine does not get overpressure.

4. Gate Valves: These are valves which allow or prevent the flow of compressed air and there are no in between states. In the PET blow molding process, we place valves in various locations, such as the preheating chamber or the blowing head.

The Impact of High-Pressure Valves on PET Blow Molding

Ensures consistent product quality and reduced defects.

Contributes to efficient production by minimizing downtime and optimizing blowing process.

Prevents equipment damage and accidents by releasing excess pressure.

Reduces maintenance costs and improves machine efficiency, leading to long-term cost savings.

Maintenance and Inspection of High-Pressure Valves in PET Blow Molding Machines

Optimum functioning and durability of high pressure valves can be maintained by regular inspection process including maintenance. If any maintenance is ignored, there are chances of failure, delay in equipment availability and many other such adverse effects.

1. Key Maintenance Tasks: Inspect valves on a regular basis for wear, corrosion, leaks or any other malfunction. Lubricate valve stems and packing as directed by the manufacturer to reduce friction and abrasion associated with premature failure. Replace valve packing whenever necessary to avoid leaks. Also inspect valve seats and stems for damage or repairs. Valves should be tested periodically for operation at the correct pressure setting.

2. Inspection Frequency: Valve inspections and maintenance frequency depends on the operating environment, valve type, and manufacturer’s recommendations. A general guideline is to check valves daily for leaks and unusual noises, weekly for lubrication and wear, monthly for a thorough inspection, and annually for comprehensive disassembly and cleaning.

Common Problems and Troubleshooting

Why valves are inspected and serviced varies depending on the operating conditions, type of valve and instructions provided by the manufacturers. Another common approach is to check the valves for leaks and abnormal noises every day, lubricate the valves and assess their wear once a week, perform a detailed and thorough evaluation of the valves on a monthly basis and finally disassemble and clean all parts of the valves once a year.

Choosing pneumatic products is important in terms of safety, efficiency, and longevity, so one should choose good quality pneumatic products. However, demanding industrial applications are challenging, and substandard parts can lead to frequent breakdowns, high maintenance costs, and safety hazards. VS Enterprise’s Mercury Pneumatics products are designed under pressure to minimize downtime and maximize productivity, so you are investing in components that will perform under pressure.

Common Problems and Troubleshooting for High-Pressure Valves in PET Blow Molding Machines

Like any other part of automated equipment, high-pressure valves in PET blow molding machines can develop a variety of problems over time. The following are frequently occurring problems and their solutions:

Leaking Valves: This problem can come from many factors such as wear of packing, loosening of valves, etc. Check the packing, inspect the valve seat, control connections, and analyze the corrosion to solve this problem.

Sticking Valves: Debris, corrosion, or improper lubrication can cause issues. Troubleshooting involves cleaning the valve, lubricating the stem, and inspecting for corrosion, which can be repaired or replaced.

Incorrect Pressure Settings: Any pressure gauge may have problems due to improper calibration or any mechanical faults. Troubleshooting in this context includes checking the calibration, correcting such mechanical faults and replacing the pressure where necessary.

Excessive Noise: Cavitation, loose parts or mechanical problems can cause this problem. Check that the valve is installed correctly and is operating at the correct pressure, inspect for loose parts, and perform a thorough inspection for troubleshooting.

Frequent Failures: What leads to problems with the valve are defects, incorrect installation or overuse. Diagnostics suggests replacing valves, checking their installation, and performing preventive maintenance in order to prolong the usage and functionality of the valves.

Conclusion

Selecting the right high-pressure valve for your needs is essential for achieving reliable performance, safety, and efficiency in applications like PET blow molding. By considering factors such as valve type, pressure requirements, material compatibility, and maintenance needs, you can ensure that your valve choice aligns with your operational demands. Properly chosen valves not only enhance production quality but also reduce downtime, minimize maintenance costs, and improve overall equipment longevity. Taking the time to evaluate your specific application needs and consult with manufacturers or specialists can make a significant difference in the performance and durability of your high-pressure systems.