In today’s rapidly evolving construction landscape, Building Information Modeling (BIM) stands out as a pivotal advancement reshaping how projects are conceived, planned, and executed. This digital representation of physical and functional characteristics of a facility has become an essential tool in the construction industry. For civil engineers, architects, and steel fabricators, understanding and leveraging BIM can significantly enhance project outcomes. This blog post explores the integration of BIM with structural steel detailing, highlighting its benefits and techniques for successful implementation.

Building Information Modeling in Construction

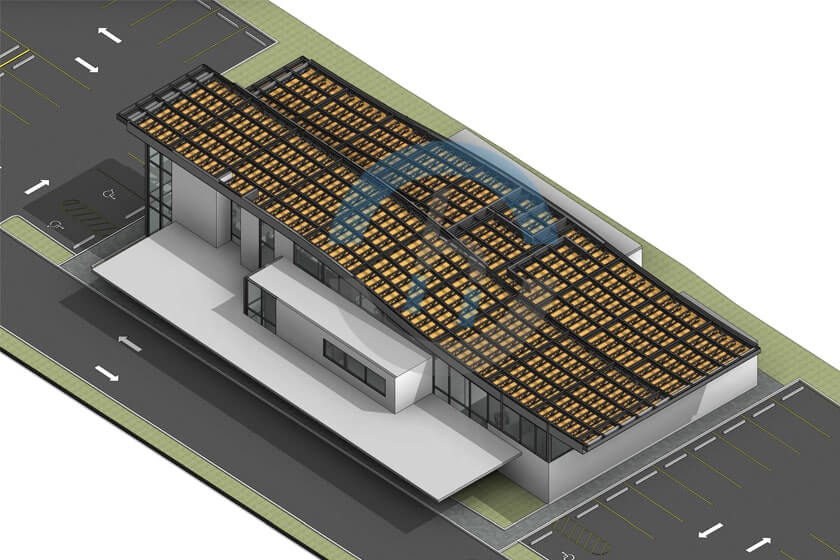

BIM is more than just a tool; it’s a process that generates and manages digital representations of physical spaces. By facilitating a collaborative environment, BIM helps teams visualize the intricate details of a project before ground is broken. This foresight allows for better planning, resource management, and decision-making throughout the construction lifecycle.

The adoption of BIM in the construction industry is growing rapidly. It enables stakeholders to work with a shared dataset, reducing misunderstandings and miscommunications. Architects, engineers, and contractors can all benefit from a cohesive view of the project, which fosters collaboration and improves overall efficiency. This unified approach helps in reducing costs and timelines, while also enhancing quality control.

For those involved in structural steel detailing, BIM offers a platform to integrate precision and innovation in their workflows. The shift towards digital design is not just a trend but a necessity for staying competitive. By adopting BIM, professionals can ensure that their projects are not only feasible but also optimized for performance and sustainability.

The Importance of Integrating BIM with Structural Steel Detailing

Structural steel detailing is a critical phase in construction that requires meticulous attention to detail. Integrating BIM into this process enhances accuracy and reduces the likelihood of errors. The seamless integration of these two components leads to more efficient project outcomes, minimizing rework and ensuring precise execution.

One of the primary advantages of integrating BIM with structural steel detailing is the ability to create highly detailed, accurate models. These models enable stakeholders to visualize complex structures and anticipate potential challenges before they occur in the physical world. This proactive approach significantly reduces risk and uncertainty.

Furthermore, the integration of BIM enhances collaboration among project stakeholders. By working from a single source of truth, engineers, fabricators, and architects can ensure alignment on project objectives. This synergy not only streamlines the construction process but also promotes innovation and creativity within teams.

Benefits of BIM in Structural Steel Detailing

Enhanced accuracy is one of the standout benefits of BIM in structural steel detailing. By providing a comprehensive view of the project, BIM allows for precise measurements and specifications. This level of detail is crucial for ensuring that the steel components fit together seamlessly, reducing the need for costly adjustments on-site.

Reduced errors are another significant advantage of using BIM. Traditional methods of steel detailing are prone to mistakes due to manual calculations and drawings. However, with BIM, these errors are minimized as the software automatically updates changes across the model. This consistency ensures that all stakeholders are working with the most current data.

Improved project efficiency is achieved through BIM’s ability to streamline processes and enhance communication. The software facilitates the sharing of information among team members, promoting transparency and reducing the time spent on rework. This efficiency translates to faster project completion times and lower overall costs.

Techniques for Integrating BIM with Structural Steel Detailing

Successfully integrating BIM with structural steel detailing requires the use of advanced software tools and collaborative practices. Software like Autodesk Revit and Tekla Structures are popular choices among professionals for their robust capabilities in modeling and detailing.

These tools offer a range of features designed to optimize the detailing process. They allow for the creation of detailed 3D models that can be easily modified and updated. This flexibility is crucial for accommodating changes throughout the project lifecycle, ensuring that the final structure meets all design specifications.

Collaborative practices are equally important in this integration. By fostering open communication and information sharing among team members, projects can benefit from enhanced problem-solving and innovation. Implementing regular coordination meetings and utilizing cloud-based platforms can further improve collaboration.

Future Trends in BIM and Steel Detailing

The future of BIM in structural steel detailing is promising, with several trends shaping the industry’s direction. One such trend is the increasing use of artificial intelligence and machine learning to enhance BIM capabilities. These technologies can automate routine tasks and provide predictive insights, further improving efficiency and accuracy.

Virtual reality (VR) and augmented reality (AR) are also making their way into the field, offering immersive experiences that enhance understanding and communication. These technologies allow stakeholders to explore models in a realistic manner, aiding in decision-making and reducing the likelihood of errors.

Sustainability is another key focus for the future of BIM. As environmental concerns become more pressing, BIM is being used to design structures that are not only functional but also environmentally friendly. By simulating various scenarios, BIM can help teams select materials and designs that minimize environmental impact.

Conclusion

The integration of BIM with structural BIM services is not just a technical enhancement but a strategic advantage in the construction industry. By staying updated with technological advancements, professionals can ensure their projects are executed with precision and efficiency.

The benefits of this integration—enhanced accuracy, reduced errors, and improved efficiency—demonstrate the importance of adopting BIM in your workflows. By doing so, you position yourself at the forefront of innovation, ready to tackle the challenges of modern construction.

For those eager to explore the full potential of BIM, consider engaging with experts in the field. By collaborating with professionals who specialize in BIM and steel detailing, you can gain valuable insights and strategies to optimize your projects. In a world where technology and construction are increasingly intertwined, staying informed is your key to success.